Ni-San Cords was born out of decades of experience and zeal to bring quality products to an ever-growing electric cable and wire market in India.

What started as a power cord manufacturing business in 1986 is today the most preferred and trusted partner of leading OEMs in India.

Established in 2007, Ni-San Cords has emerged as the most preferred and trusted partner for leading OEMs in India.

At Ni-San, we have worked closely with our customers for decades, understanding their requirements; offering solutions and products that best suit their needs.

In addition to manufacturing power cords, we also manufacture general-purpose cables for domestic usage. We have recently entered the arena of manufacturing Wire Harnesses.

With two plants in Kolhapur and a new, modern manufacturing plant in Pune, Ni-San Cords is expanding by leaps and bounds in developing and manufacturing quality products.

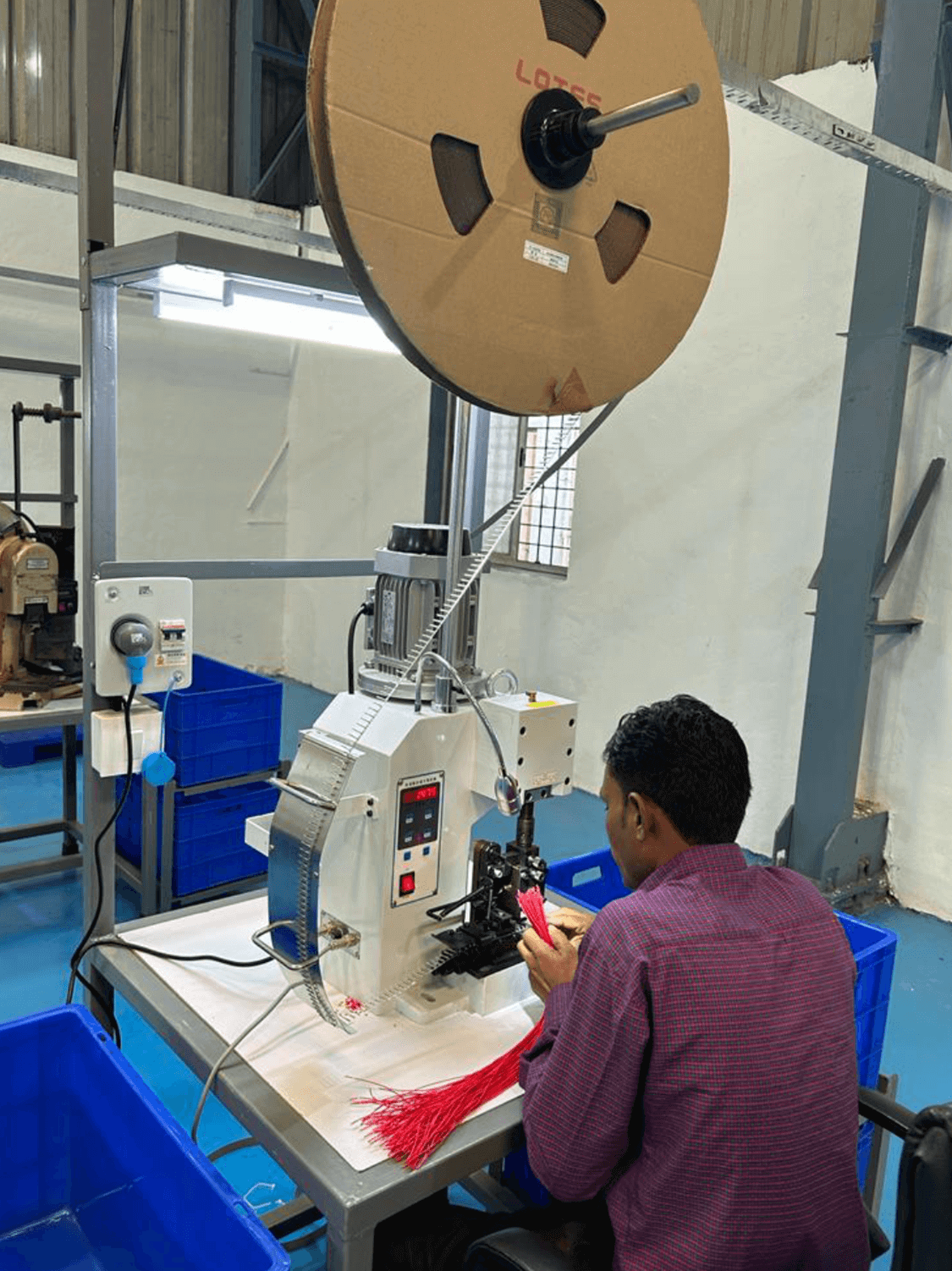

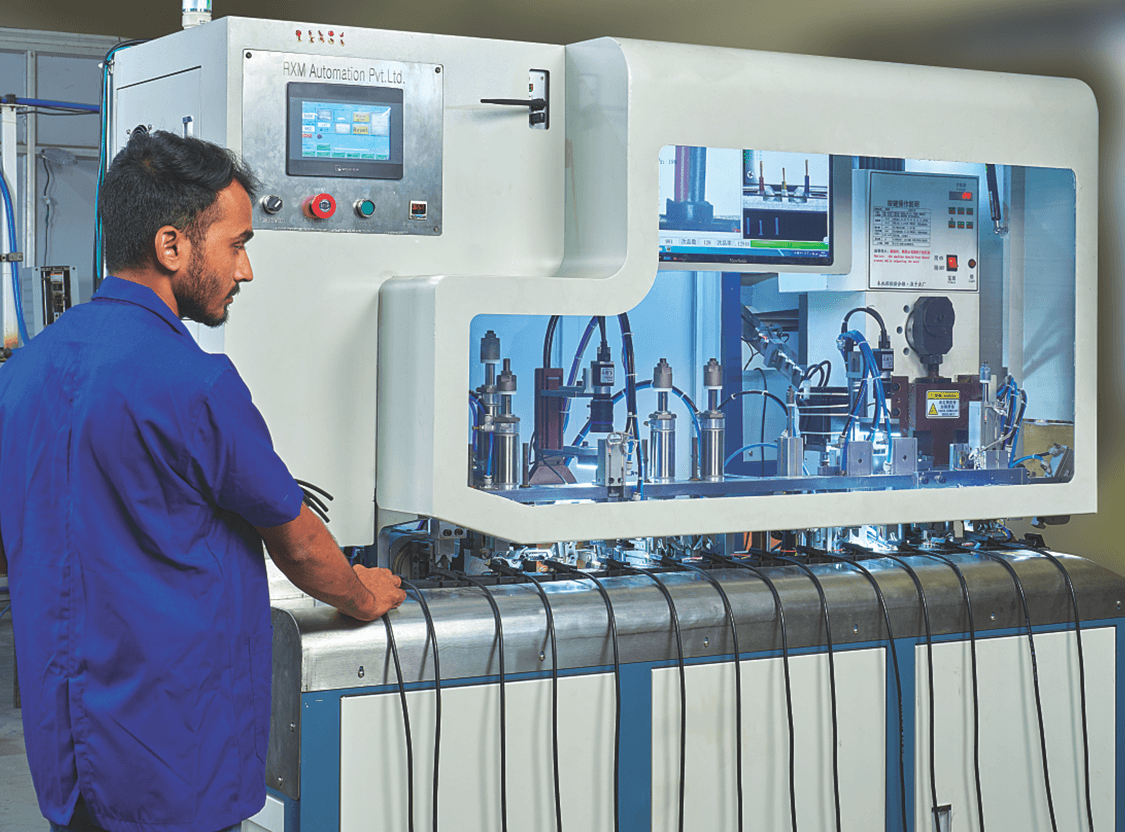

State-of-the-art manufacturing process and systems in use

Product optimized through computer-aided designing

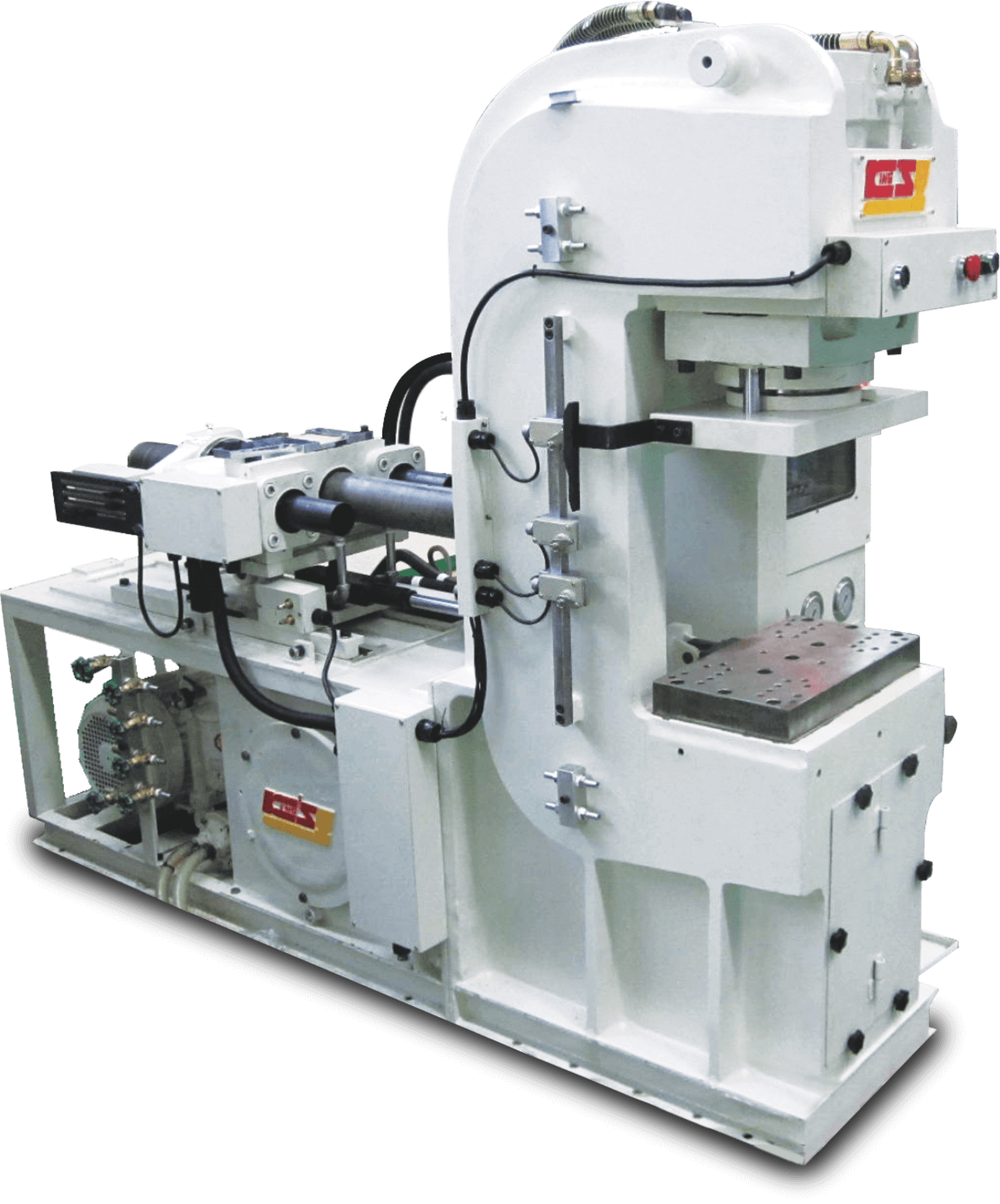

State-of-the-art power cord injection moulding machines with precise control of process parameters

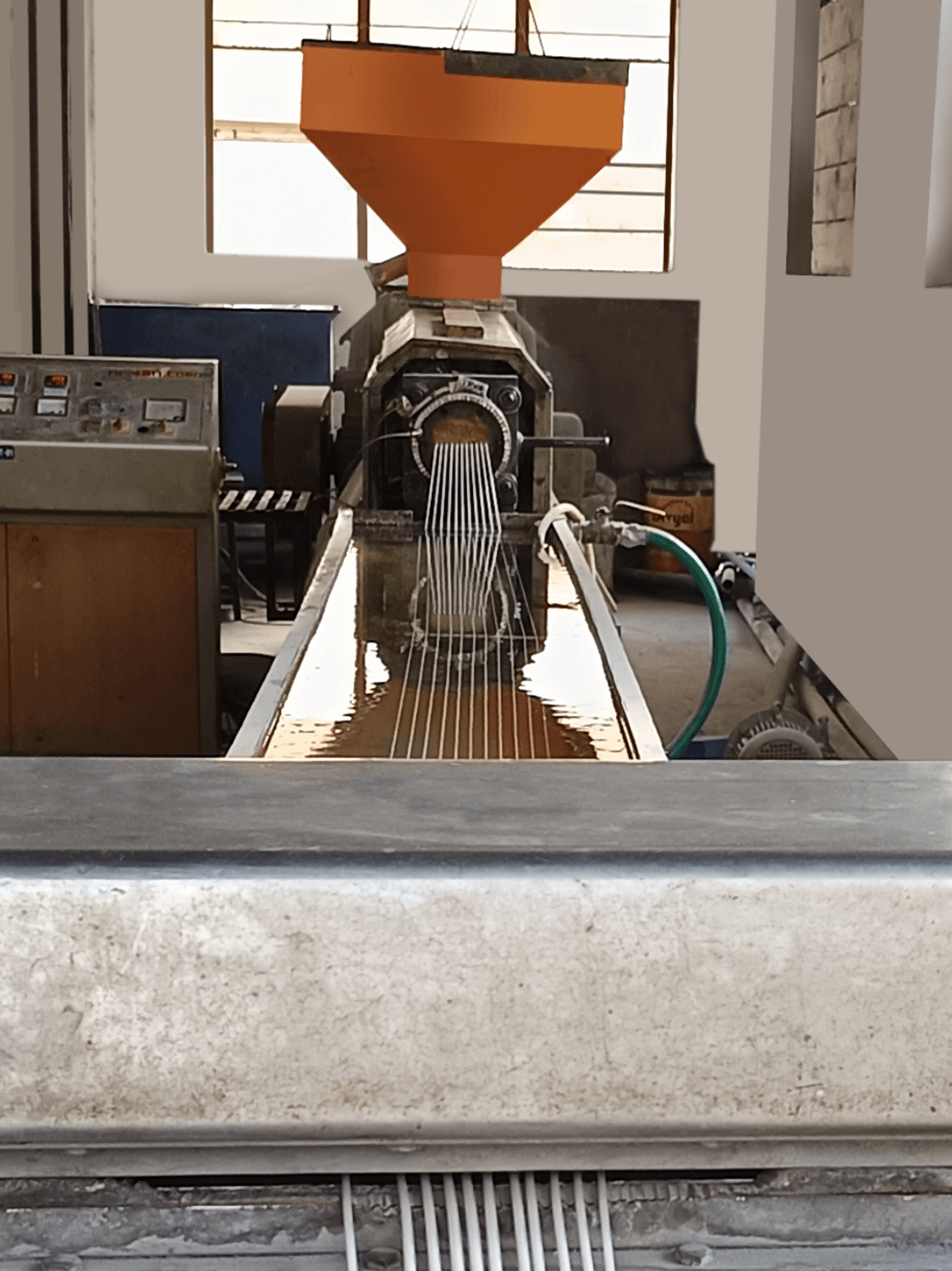

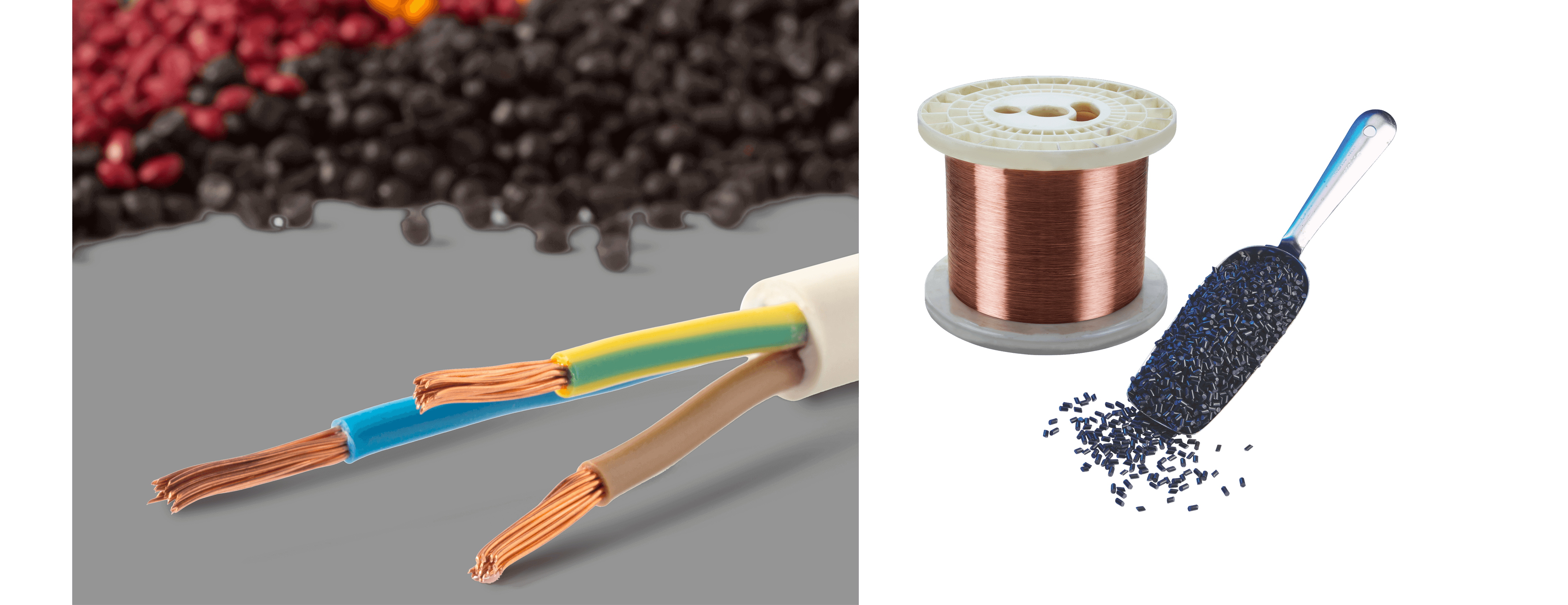

Copper drawing machines from Φ 8 mm – Φ 0.15 mm.

High speed Bunching machine with precise lay length

and tension control

PVC compounding : Φ 90 mm Extrusion

plant with High speed mixer

and cooler

Cable : Φ 65 mm Cable

extrusion plant with on line

diameter controller and

spark tester

We source high grade pure electrolytic copper. Electrolytic copper, being the highest grade of copper (more than 99.95%), delivers maximum conductivity. Even negligible impurity in copper can hamper the conductivity hence Ni-San uses only this grade of copper in making of wires and cables. Wire drawing & Copper annealing are our in-house facilities. Annealing makes the copper wire ductile & helps remove the internal stresses, making it easy in wire drawing & maintaining the strength, which are a crucial quality norm. No wonder, Ni-San wires & cables provide extraordinary thermal and electrical support. Our high quality PVC insulation is flexible & resistant to cracking and is free from cuts & abrasions. All our products bear our brand name, size & ISI mark.

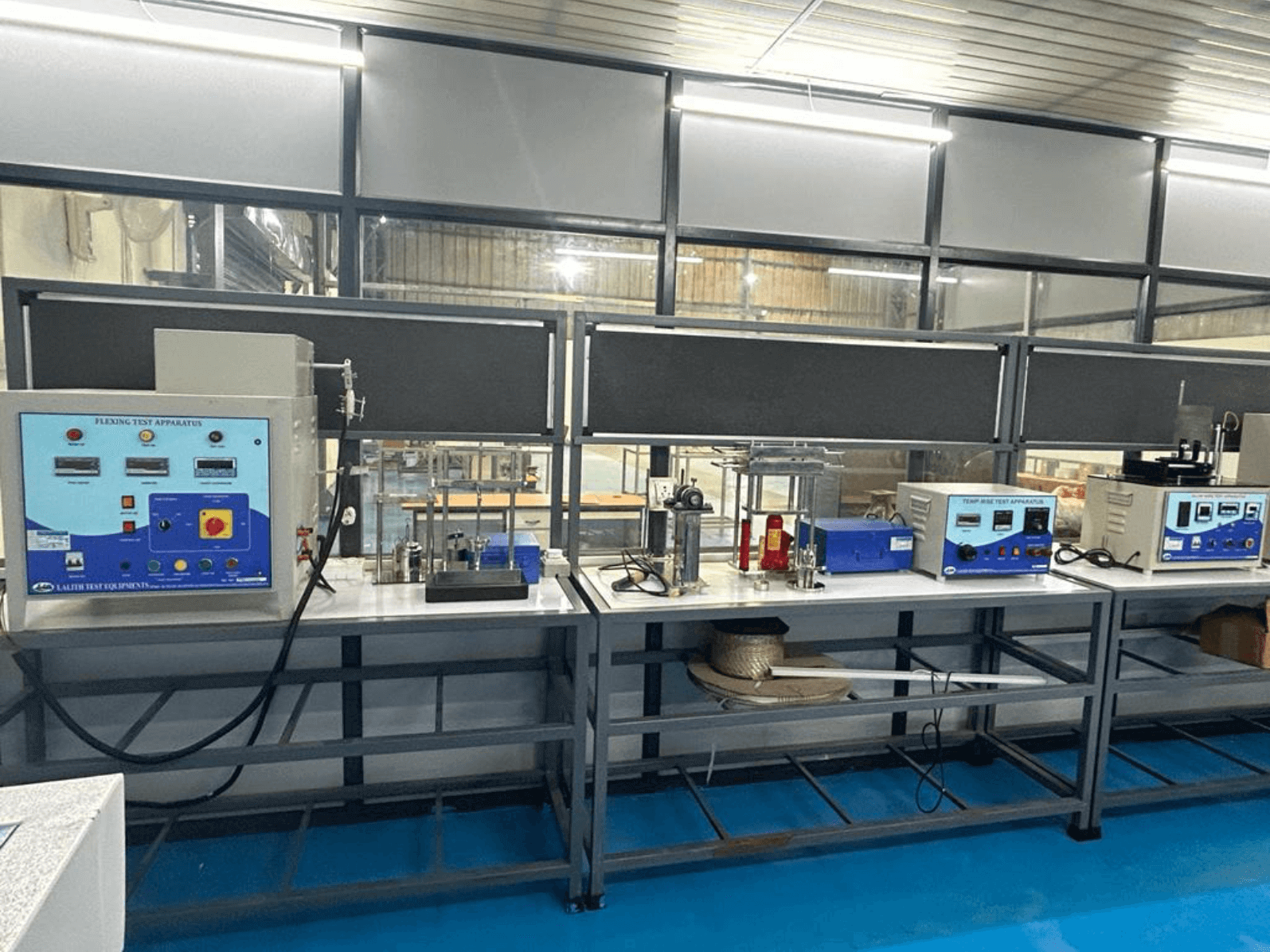

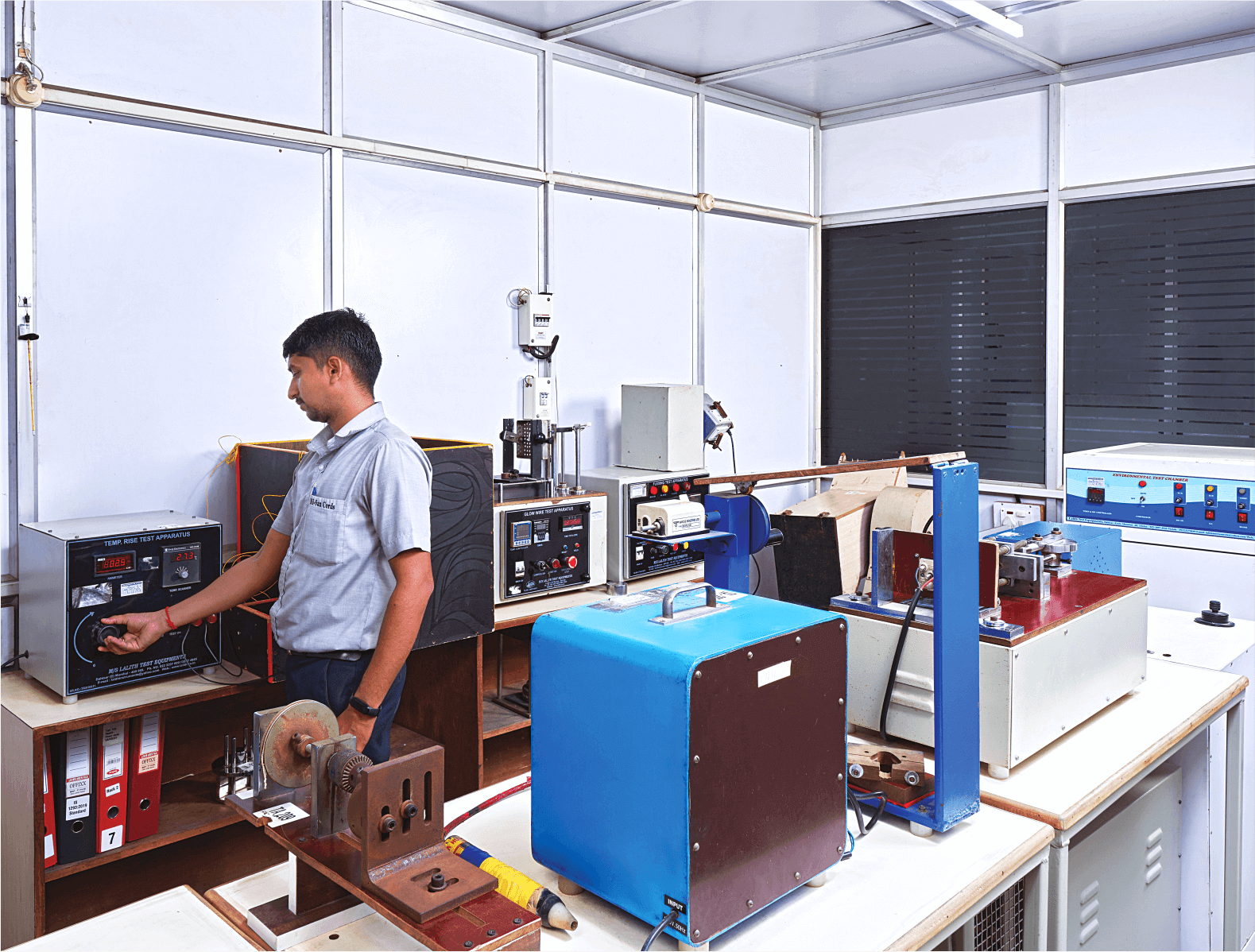

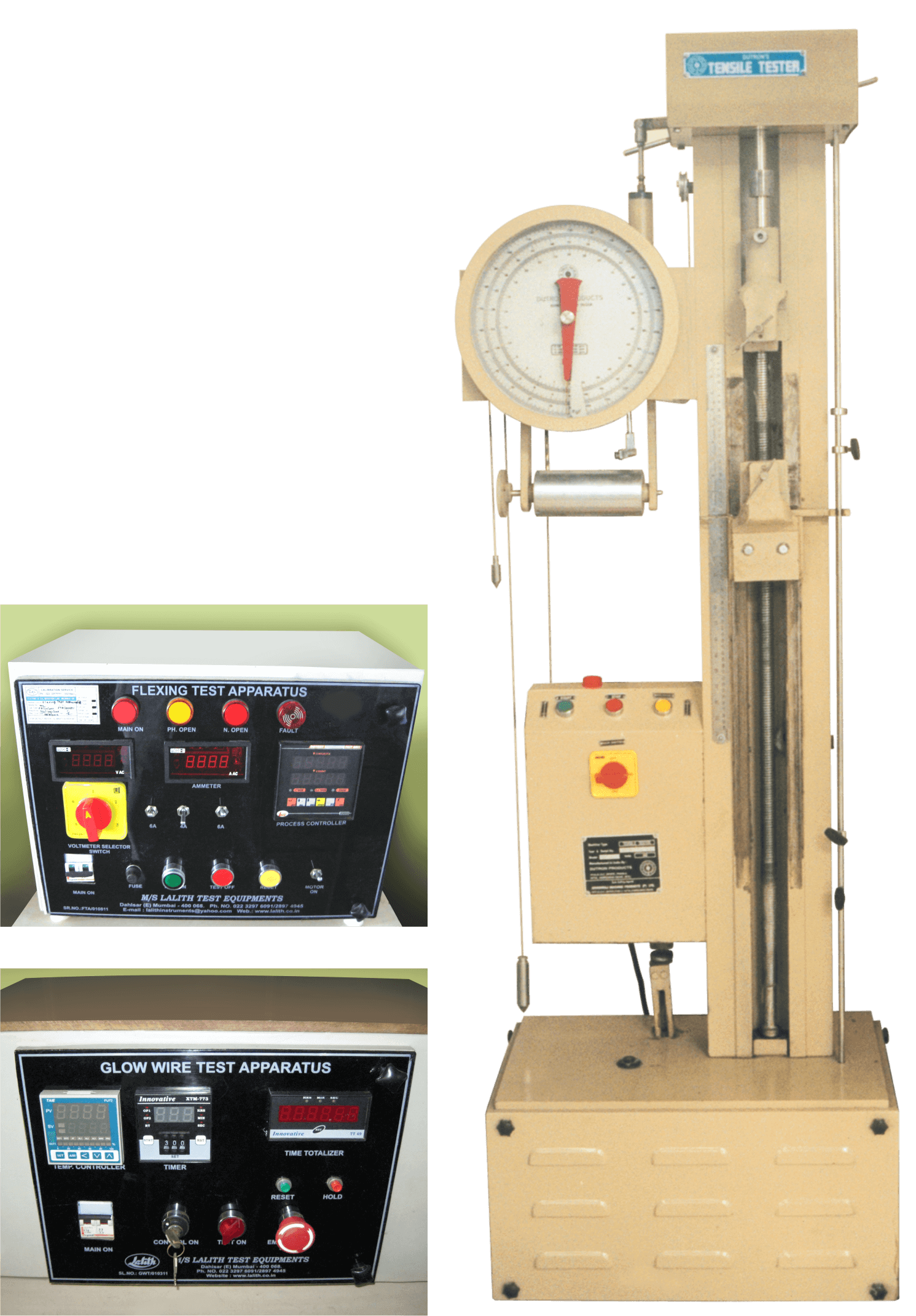

- Ageing

- Endurance

- Electrical

- Mechanical

Ni-San's ISO 9001:2015 certification is a recognition of having adhered to international standards dedicated to Quality Management Systems (QMS) which is the aggregate of all the processes, resources, assets, and cultural values that support the goal of customer satisfaction and organizational efficiency.

Ni-San cords has implemented stringent process controls, monitoring and inspection methods & machinery to manufacture Quality products. Thus these products mean reliable operation and long life of equipment. Hence Ni-San is a preferred source for high grade products for many original equipment manufacturers in India. Ni-San offers design and manufacture of Special Application cords manufactured to customer specifications with prototypes. No compromise is made in material inputs or processes including specially sourced high purity annealed Copper wire. With complete Customer orientation in mind, testing protocols are met with timely delivery at competitive prices. The same quality sanctity & commitment is being maintained for the newly introduced Wire Harnesses through adoption of Best Practices.

Ni-San can walk you through the processes & controls for complete satisfaction before placing an order as a part of complete customer orientation with timely delivery at competitive prices.